Regular inspection and maintenance of oil pan seals, turbo oil seals, and gasket seals are essential to identify signs of wear, damage, or leakage. Proper lubrication and adherence to recommended service intervals can help extend the lifespan of these seals. When replacement is necessary, selecting the correct seal type and ensuring proper installation are critical to maintaining the integrity and performance of the engine.

What is an Oil Seal?

4. Fluroelastomer also popularly known as Viton. – The high temperature resistant material used in places where temperature is more than 120 Degree Celcius.

Rubber type

Maintenance and Replacement:

There are several materials used to manufacture oil seals. They are discussed below.

1 inch rubber gasket. In certain types of electrical conduits and junction boxes, these gaskets are used to create a barrier against moisture and dust, protecting sensitive electrical components from environmental damage. Here, the non-conductive nature of rubber adds an extra layer of safety by preventing current leakage.

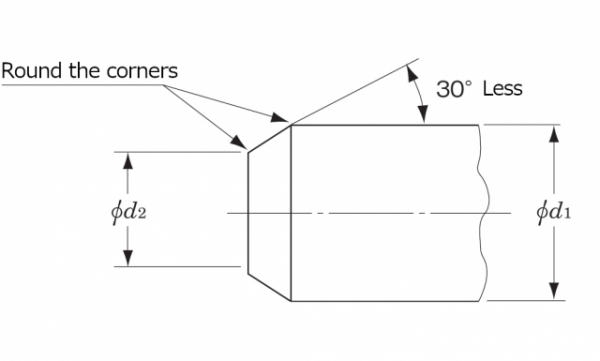

1 inch rubber gasket. In certain types of electrical conduits and junction boxes, these gaskets are used to create a barrier against moisture and dust, protecting sensitive electrical components from environmental damage. Here, the non-conductive nature of rubber adds an extra layer of safety by preventing current leakage.Furthermore, the 30-50-10 oil seal is designed to withstand prolonged use and harsh operating conditions. This makes it suitable for a wide range of applications, including automotive, industrial, and agricultural machinery.